Product Introduction

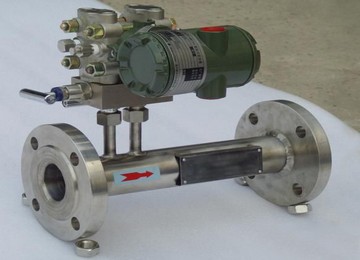

This type of meter also operates by detecting vortices. However, in this device, the fluid is forced into swirl condition by swirl-producing vanes, or swirl blades. The center of the vortex becomes displaced from the meter centerline and follows a helical path (precession) as it moves downstream through an enlargement. This precession causes fluctuations in fluid pressure and velocity. A sensor placed downstream from the swirl blades detects and measures the frequency of the precession. This frequency is linearly proportional to flow rate. Vortex precession flowmeter for measuring volumetric flow, temperature, pressure, density, and mass flow using a single meter

Measures most gases, liquids and steam without the need to recalibrate

Cost effective, accurate and reliable meter for volumetric and mass flow measurement

Remote monitoring and integration to DCS using HARTand Modbus communication protocols

Significant cost savings through reduced installation costs, wiring runs and services support.

Ideal for high temperature and high velocity steam

Power Generation steam applications

Industrial HVAC, district energy management

Commercial building, campus and facility energy management

Oil & gas allocation of natural gas

Petrochemical mass balancing, reaction processes heating

Pana Flows multi variable design consists of a vortex shedding velocity sensor, an RTD temperature sensor and a solid-state pressure transducer that measures the mass flow rate of steam, gases and liquids. The Pana Flow vortex flow meter measures velocity, temperature and pressure in the same location, which provides more accurate process measurement. Integrating pressure and temperature simplifies system complexity and helps minimize initial capital costs, as well as reduce the installation costs. A wide range of options and meter configurations are available to meet your specific application requirements

Main Parameter

Flow meter Accuracy

Accuracy 0.65 % of rate for liquids (Accuracy 1.00% for line size 6-in (150 mm) and greater)

Turn down

38:1

Output

· 4-20 mA with HART®

· 4-20 mA with HART® and Scalable Pulse Output

· FOUNDATION™ fieldbus with 2 Analog Input blocks, 1 Backup Link Active Scheduler function block, and 1 Integrator function block (1 PID function block optional)

Wetted Material

Stainless Steel - 316/316L and CF3M

Flange Options

ANSI Class 150 to 900

Operating Temperatures

-330¡ãF to 800¡ãF (-200¡ãC to 427¡ãC)

Line Size

Flanged - 1-in to 12-in (25 to 300 mm)

Accuracy 1% for gas and steam (Accuracy 1.50% for line size 6-in (150 mm) and greater)

Nickel Alloy - C-22 and CW2M

Consult factory for other wetted material options

DIN PN 10 to PN 160

JIS 10K to 40K

Flanges are available in a variety of facings

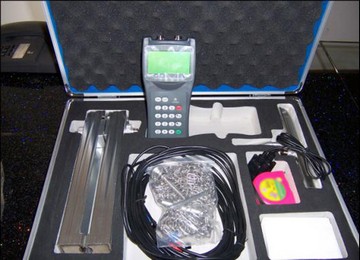

Figure Photos

B/L of The History Trading