Introduction of Underground Mining Use PVC Gas Drainage Hose

Coupling hose for gas drainage in coal mine is taking PVC (polythylene) as main material, with spiral steel frame with one-step molding technology; it is used for flexible connection between negative pressure gas drainage pipeline and device under the well of coal mine, which has solved the problem of gas tightness for connection between negative pressure gas drainage pipeline and device, and it is applicable to the connection between gas drainage pipeline and gas main pipeline of this coal seam.

Model and specification of Underground Mining Use PVC Gas Drainage Hose

PVCGR-KW (- 0.097)/ φ25, φ32, φ40, φ44, φ50, φ63, φ75, φ90, φ110

For example: PVCGR-KW (- 0.097)/32 refers to coupling hose for gas drainage in coal minethat nominal pressure is -0.097MPa and nominal internal diameter is 32mm.

Characteristics and explanation of Underground Mining Use PVC Gas Drainage Hose

1. The coupling hose using steel frame supporting has a certain strength and hardness; negative pressure resistance is -0.097MPa, which can be kept for 100 hours without partial absorption and damage, so it can meet the requirement of negative pressure drainage under the well.

2. The bending and scalability is high, it can keep away from barrier effectively under complex condition under the well.

3. This product has excellent flame retardant and antistatic performance, and the special material used on surface can prevent scratch from poignant articles.

4. It has good acid and alkali resistant performance, which can’t be corroded by gas, liquid and other medium with strong corrosion easily.

It is applicable to flexible connection for various models of gas drainage pipes.

the secondary pressure grouting gas drainage sealing apparatus comprising drainage pipe and pouch, characterized further comprising: a tubular second into pulp device, connecting both sides of the device is connected to the secondary slurry into the drainage pipe and Drainage pipe on both sides are set with a plug, set the pocket between each plug and the secondary side into the plasma apparatus similar features on the exhaust pocket; the second into the plasma device is provided with three holes into the plasma and in communication with the center, respectively, with two-way valve into the slurry hole, both sides are on the same side of the capsular bag in communication with the space between the middle and the two holes into the plasma pouch space communication.

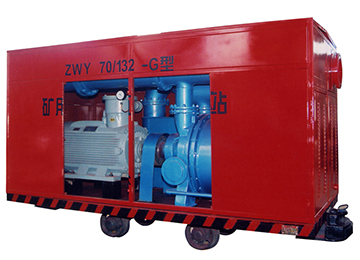

Photos of Underground Mining Use PVC Gas Drainage Hose