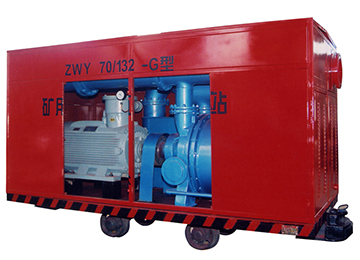

Introduction of Underground Mining Gas Drainage Hose Gas Drainage Pipe Coal Mine Gas Drainage Tube

Polyethylene gas drainage tube product introduction

Gas explosion is the most common accident in coal mine accidents. In order to ensure the safe production of coal mines, all units and departments pay great attention to the study of gas. At present, the most common measure in coal mine production is to pump gas from special gas. To ensure the safety of mine operations. Gas pipelines are dedicated pipelines for the extraction of gas from coal mines. The performance of gas pipelines directly affects the safe production of coal mines. It can be seen that the performance of gas drainage pipelines has a major impact on the safe production of coal mines.

Polyethylene gas drainage pipe product structure

The polyethylene gas drainage pipe is made up of two layers of the same width of the fastening plastic plate inside and outside. It is designed as a 10,000-hole "work" shape and a closed structure. The combination of the plate and the plate is sealed by a labyrinth. With a special adhesive. The outer wall of the pipeline is covered with a high-impact, high-flame-retardant, anti-static polymer material layer. The inner wall of the pipeline adopts a special antistatic agent produced by our company, so that the coiled pipe not only has strong impact resistance and anti-negative pressure performance. Moreover, it can fully guarantee the flame retardant and antistatic requirements of the pipeline under the coal mine. The pipeline solves the manufacturing technology and connection technology of large-diameter gas drainage pipe with diameter above DN5, and provides a high strength, antistatic, high flame retardant, corrosion resistant, light weight, easy to handle and easy to install for the mining industry. Caliber pipe.

Polyethylene gas drainage pipe application range

1. Gas drainage pipes used in underground coal mines;

2. Ventilation pipes for underground coal mines;

3. Flame retardant pipelines;

4. Antistatic pipeline;

5. Negative pressure pipeline.

Photos of Underground Mining Gas Drainage Hose Gas Drainage Pipe Coal Mine Gas Drainage Tube