Introduction of QW Submersible Mud Pump

QW submersible mud pump is a new generation of pump products developed on the basis of the introduction of foreign advanced technology and combined with the characteristics of domestic water pumps. It has the characteristics of remarkable energy saving effect, anti-winding, no clogging, automatic installation and automatic system. It has a unique effect in discharging solid particles and long-fiber waste.

This series of sewage pumps uses a unique impeller structure and a new mechanical seal to efficiently transport solids and long fibers. Compared with the conventional impeller, the impeller is in the form of a single flow channel or a double flow channel. It is similar to a curved pipe of the same cross-section. It has very good over-flow and is equipped with a reasonable volute to make the pump efficient. High and impeller dynamic and static balance test, so that the pump has no vibration during operation.

Characteristic of QW Submersible Mud Pump

1. The unique single-piece or double-blade impeller structure greatly improves the dirt passing ability, and can effectively pass 5 times of the fiber diameter of the pump and the solid particles with a diameter of about 50% of the pump diameter.

2. The mechanical seal uses a new hard and corrosion-resistant tungsten-titanium material, which enables the pump to run safely for more than 8,000 hours.

3. The overall structure is compact, small in size, small in noise, remarkable in energy saving effect, convenient in maintenance, no need to build a pump room, and can work in submerged water, greatly reducing the project cost.

4. The pump sealing oil chamber is provided with a high-precision anti-interference water leakage detecting sensor, and a thermal element is embedded in the stator winding to automatically protect the pump motor.

5. The automatic control cabinet can be equipped according to the user's needs to automatically protect the pump from water leakage, leakage overload and over-temperature, which improves the safety and reliability of the product.

6. The float switch can automatically control the start and stop of the pump according to the required liquid level change, without special care, and is extremely convenient to use. 7. The QW (WQ) series can be equipped with a dual-rail automatic coupling installation system according to the user's needs. It brings more convenience to installation and maintenance, and people do not have to enter the sump for this purpose.

8. It can be used in full lift without ensuring that the motor will not be overloaded.

9. There are two different installation methods, fixed automatic coupling installation system and mobile free installation system.

Parameter of QW Submersible Mud Pump

|

Model |

caliber |

Flow |

head |

Power |

speed |

effectiveness |

|

QW25-8-15-1.1 |

25 |

8 |

15 |

1.1 |

2825 |

38.5 |

|

QW32-12-15-1.1 |

32 |

12 |

15 |

1.1 |

2825 |

40 |

|

QW40-15-15-1.5 |

40 |

15 |

15 |

1.5 |

2840 |

45.1 |

|

QW40-15-30-2,2 |

40 |

15 |

30 |

2.2 |

2840 |

48 |

|

QwW50-20-7-0.75 |

50 |

20 |

7 |

0.75 |

1390 |

54 |

|

QwW50-10-10-0.75 |

50 |

10 |

10 |

0.75 |

1390 |

56 |

|

QW50-20-15-1.5 |

50 |

20 |

15 |

1.5 |

2840 |

55 |

|

QW50-15-25-2.2 |

50 |

15 |

25 |

2.2 |

2840 |

56 |

|

QW50-18-30-3 |

50 |

18 |

30 |

3 |

2880 |

58 |

|

QW50-25-32-5.5 |

50 |

25 |

32 |

5.5 |

2900 |

53 |

|

QW50-20-40-7.5 |

50 |

20 |

40 |

7.5 |

2900 |

55 |

|

QW65-25-15-2.2 |

65 |

25 |

15 |

2.2 |

2840 |

52 |

|

QW65-37-13-3 |

65 |

37 |

13 |

3 |

2880 |

55 |

|

QW65-25-30-4 |

65 |

25 |

30 |

4 |

2890 |

58 |

|

QW65-30-40-7.5 |

65 |

30 |

40 |

7.5 |

2900 |

56 |

|

QW65-35-50-11 |

65 |

35 |

50 |

11 |

2930 |

60 |

|

QW65-35-60-15 |

65 |

35 |

60 |

15 |

2930 |

63 |

|

QW80-40-7-2.2 |

80 |

40 |

7 |

2.2 |

1420 |

52 |

|

QW80-43-13.3 |

80 |

43 |

13 |

3 |

2880 |

50 |

|

QW80-40-15-4 |

80 |

40 |

15 |

4 |

2890 |

57 |

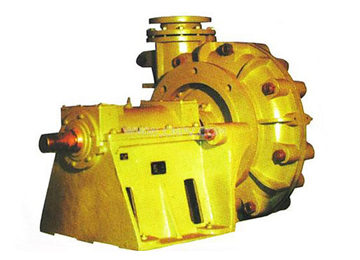

Photos of QW Submersible Mud Pump