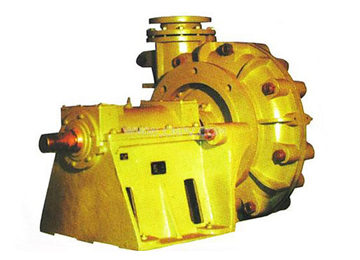

Introduction of NL Sewage Slurry Pump

The main components of the NL sewage slurry pump are composed of a volute, an impeller, a pump seat, a pump casing, a support cylinder, a motor base and an electric motor. The volute, pump seat, motor seat and impeller nut are cast iron casting, good corrosion resistance and corrosion resistance, and the processing technology is convenient. The impeller is a three-piece single-chord curved blade. The semi-closed impeller is used, and the malleable cast iron is used, so the strength is high and corrosion resistance; the processing is convenient, the passability is good, and the efficiency is high. In order to reduce the weight and reduce the amount of turning, the pump shaft is made of high quality carbon steel cold drawn steel. The submerged mud pump can be used vertically or obliquely, and the footprint is small. The volute needs to be buried in the working medium to work, easy to start, no need to divert water, and the direction of rotation should be clockwise from the rear of the motor. The length of the main unit is available in various specifications so that the unit can be selected according to the application.

Application range of NL Sewage Slurry Pump

1. NL sewage slurry pump is a single-stage single-suction centrifugal pump used in mining, paper making, printing and dyeing, environmental protection, graphite, mica, gold, ceramics, oil refining, petroleum, chemical, farm, salt field, iodine field, dyeing, wine making , food, fertilizer, coking, plant selection, construction, marble plant, gold mine, mud, quicksand, mud pond, sewage pond, sewage liquid to send thick liquid, loading and suspended materials sewage operation, can also be used for mine drainage and contain The fluid of the mud block.

2. If combined with high-pressure water pump and water gun, the hydraulic mechanized earthwork engineering unit can be used for land leveling, excavation and transportation of small water conservancy projects such as dredging and ponding of rivers and ponds, and urban air defense works, underground. engineering.

3. Fish farming is used to clear ponds, to increase oxygen of fish ponds.

Parameter of NL Sewage Slurry Pump

|

Model |

Rotating speed n r/min |

flow Q m3/h |

head of delivery H m |

effectiveness n % |

Motor PowerKW |

|

NL50-8 NL50A-8 |

1450 |

20-30 |

8-9 |

42 |

1.5 |

|

NL50-12 NL50A-12 |

1450 |

25-38 |

12-14 |

41 |

3 |

|

NL76-9 NL76A-9 |

1450 |

50-70 |

9-10 |

42 |

3 |

|

NL65-16 NL65A-16 |

1450 |

50-60 |

15-18 |

42 |

5.5 |

|

NL80-12 NL80A-12 |

1450 |

80-120 |

11-13 |

56 |

7.5 |

|

NL100-16 NL100A-16 |

1450 |

80-100 |

15-17 |

61 |

15 |

|

NL150-12 NL150A-12 |

1450 |

100-150 |

11-13 |

66 |

18.5 |

|

NL150-16 NL150-16 |

1450 |

120-180 |

15-20 |

68 |

22 |

Photos of NL Sewage Slurry Pump