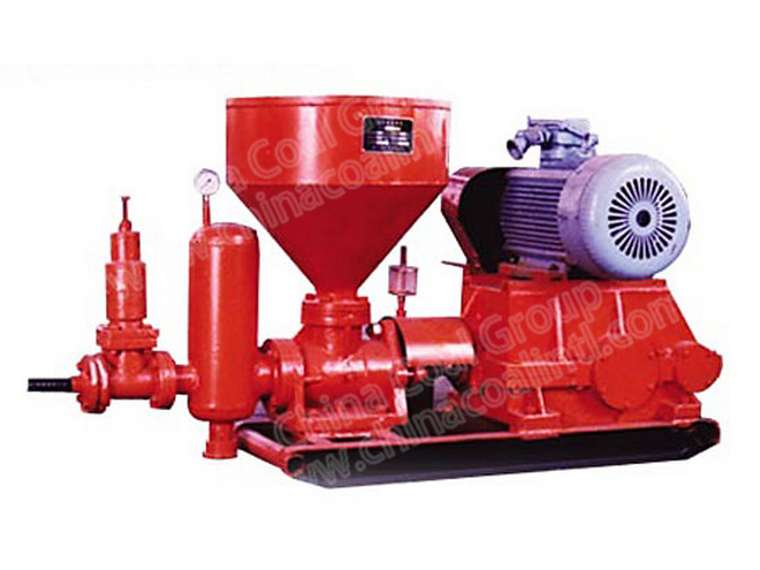

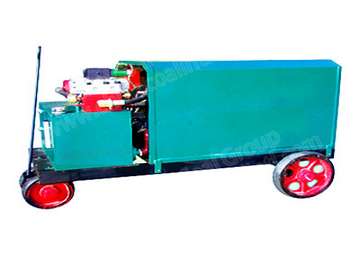

Introduction Of Hydraulic Grouting Pump

Hydraulic grouting pump is a fully hydraulic, adjustable pressure grouting pump. It uses high-pressure to spray easily solidified substance or mixture (water, mud, water glass, etc.) to the soil or rock cracks accurately so as to achieve the purpose of reducing seepage, consolidation of rock and soil.

Hydraulic grouting pump is widely used for coal, underground water well construction and engineering, but also for tunneling and maintenance, construction of dams, large bridges, high-rise buildings and various underground foundation treatment works.

Structure and working principle

Hydraulic grouting pump consists of motor, gear pumps, pressure relief valve, hydraulic valve block, cylinder, cylinder, mixers and tanks, radiators, oil filter, intake and exhaust valves and electrical control box and other components.

Motor direct drives gear pump, gear pump output pressure relief valve into the hydraulic fluid through the valve block, the hydraulic valve block control cylinder reciprocating motion, as cylinders and cylinder are synchronized movement, because of the working cylinder bore and stroke are the same, so the working cylinder and cylinder displacement and stress basically similar to each end of the cylinder valve and the exhaust set grout slurry valve, which can be the same kind of slurry suction, suction can be respectively two different the slurry.

Parameters Of Hydraulic Grouting Pump

Grouting pressure 2MPa 5MPa 8MPaOutlet flow 88L/min 85L/min 80L/min

Motor Model YBK2-180M-4

Power 22kW

Rated voltage 380/660V 660/1140V

Rated current 43.1A

Hydraulic working pressure 9.5MPa

Hydraulic System Flow 80L/min

Hydraulic oil tank 0.08m3

Weight 430kg

Outer size(L*W*H) 1550*800*720mm

Pictures Of Hydraulic Grouting Pump