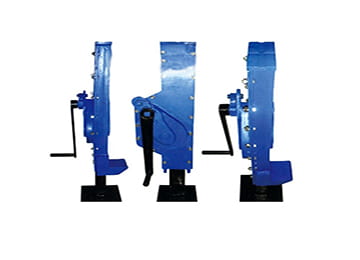

Rack Type Track Jack Instruction

1.Lifting - track jack should be smoothly completed, with a length of 1.5 meters of steel steel rod inserted into the handle hole and up and down reciprocating throw to ascend a height it is needed.2.Slow down, turn slowly drop control handle up to braking position will lever up and down throw, every reciprocating or one tooth at a time.

3.Drops - pull lever, using leverage vertical impact downhill baseboard end surface, can again down to the starting position.

4. The sliding parts often lubrication, finding the parts damaged change in time.

Rack Type Track Jack Application

Rack type track jack is mainly used for railway track laying and maintenance, such as bridge erection work is widely used for lifting and supporting the installation of various weights, and equipment. It is suitable for railway rails and auxiliary, and bridge is installed, and vehicles, equipment, weight lifting.Rack type track jack working principle is one type of manual lifting tools, compact structure, reasonable use of the rocker swing jaw moves up and down with the fixed jaw joint cooperation, promoting the rack up or down, lifting objects along lift.

Rack Type Track Jack Parameters

Model QD5Max jacking 5T

Max hook capacity 2.5T

Lifting height 160mm

Jack up height 345mm

Feet hook height 43mm

Rack Type Track Jack Photo

Products

Overview :

Total : 4

Contacts:S***r E-mail:S***r @yahoo.com

Hi,I’m interested in your Rack Type Track Jack, I would like some more details.

Customer Service:

Thanks for your support to us! And our sales will contact you soon!

Contacts:A***a E-mail:A***a @hotmail.uk

I would like to have prices for all the types of the Rack Type Track Jack.

Customer Service:

We just got your message. Our sales will contact you asap.

Contacts:S***v E-mail:S***v @s***p.rs

prices and more pics. Looking forward to your quick reply

Customer Service:

Dear Customer, We just got your message. Our sales will contact you asap.

Please leave a message

Please leave a message

Please leave a message