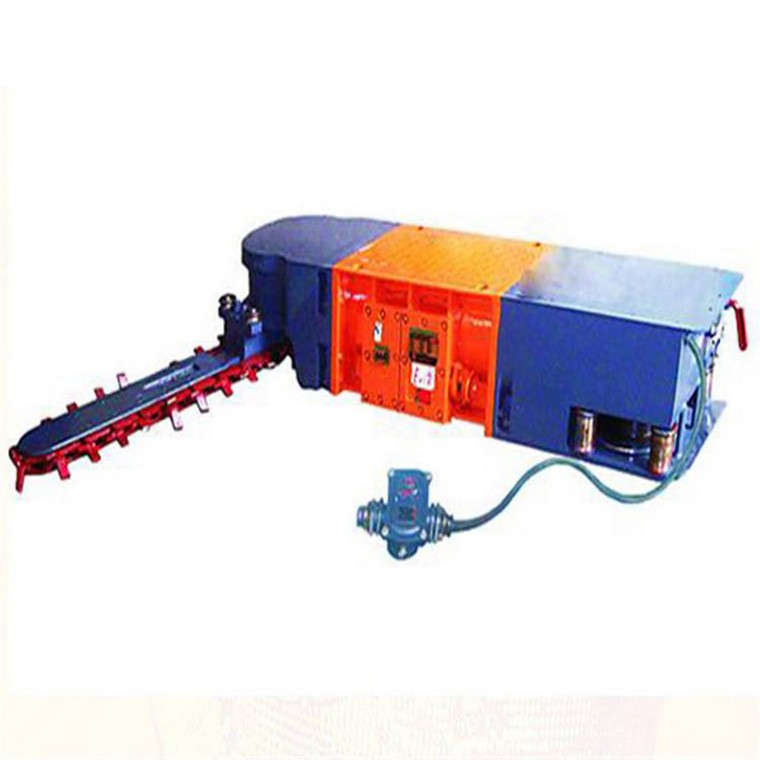

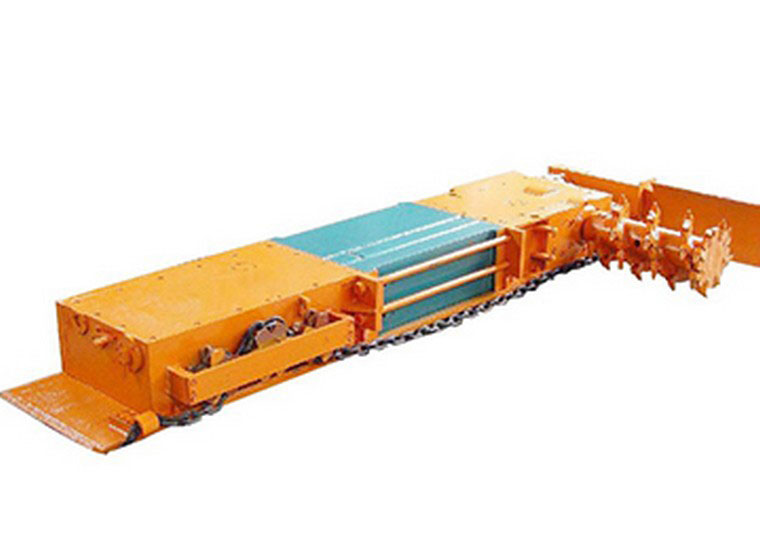

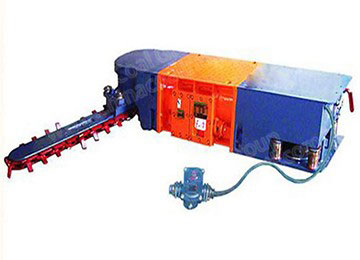

Introduction Of Coal Cutter

The coal cutter is light in weight and manufactured according to the standard of explosion-proof electrical appliances for mining. It is suitable for the construction operations of open-pit coal mines, sulfur mines, and gypsum mines.

The coal cutter is suitable for small and medium-sized coal mines, slow-thinning thin coal seams in underground mines, and extremely thin composite coal seams. The working face of the coal mining face can be used to cut the bottom groove and the top groove, so that the coal can be cut out.

The coal cutter has a good appearance, small size, and the product weight is about 200 kg lighter than similar products. It is flexible in operation and convenient to carry, which is conducive to improving work efficiency and saving costs. Suitable for use in smaller projects.

The coal cutter has two gears, high speed and low speed. It can cut coal seams at low speed, high-speed no-load traction or release rope, and is equipped with an interlocking device, so it can be automatically separated to avoid sintering of the friction plate; The two gears work together to improve work efficiency.

Parameter Of Coal Cutter

|

Traction method: traction in steel wire rope |

Motor model: YBK2—160L-4 |

|

Traction speed: 0 ~ 920mm / min |

Traction speed: 0 ~ 920mm / min |

|

Groove depth: 800 ~ 900 mm |

Rated voltage: 380V / 660V |

|

Chain cutting linear speed: 1900mm / s |

Dimensions: 1800 × 390 × 280mm |

|

Rope drum capacity: 20000mm |

Wire rope specifications: 6 × 37 (Φ10.5mm) |

|

Traction: 15.33KN |

Machine weight: 750 ± 2kg |

|

Traction power: 5KW |

Cutting power: 10KW |

|

Cooling method: water cooling |

No-load lowering speed: 4018mm / min |

|

Cooling method: Cooling in spiral water channel |

Working method: back and forth along the coal |

|

Dustproof method: Dustproof in the coal |

wall, work left and right |

|

interception section of cooling water |

Lubrication method: continuous pressureless |

|

lubrication |

|

Photos Of Coal Cutter