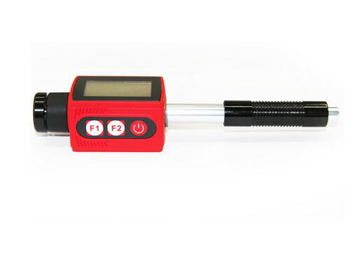

Introduction of MH100 Hardness Tester

MH100 Hardness Testera Advantages

Compact and integrated. The impact device and the main body integrated together.

Wide measuring range. Based on the principle of Leeb hardness testing theory. It can measure the Leeb hardness of all metallic materials.

Large screen LCD, showing all functions and parameters. With EL background light.

Test at any angle, even upside down.

Direct display of hardness scales HRB, HRC, HRA, HV, HB, HS, HL.

Large memory could store 100 groups (Relative to average times 32~1 ) information including single measured value, mean value, impact direction, impact times, material and hardness scale etc.

Battery information showing the rest capacity of the battery and the charge status.

User calibration function.

Software to connect to PC via USB port.

Li-Ion rechargeable battery as the power source. Charge circuit integrated inside the instrument. Continuous working period of no less than 200 hours (EL off and no printing).

Auto power off to save energy.

Outline dimensions:148mm×33mm×28mm

Main Application of MH100 Hardness Tester

Die cavity of molds

Bearings and other parts

Failure analysis of pressure vessel, steam generator and other equipment

Heavy work piece

The installed machinery and permanently assembled parts

Testing surface of a small hollow space

Material identification in the warehouse of metallic materials

Rapid testing in large range and multi-measuring areas for large-scale work piece

Testing Range of MH100 Hardness Tester

The model includes D type, C type and DL type according to the impact device.

Testing range refer to Table 1 and Table 2 in the Appendix.

Parameters of MH100 Hardness Tester

Error and repeatability of displayed value see Table1-1 below.

Table 1-1

|

No. |

Type of impact device |

Hardness value of Leeb standard hardness block |

Error of displayed value |

Repeatability |

|

1 |

D |

760±30HLD 530±40HLD |

±6 HLD ±10 HLD |

6 HLD 10 HLD |

|

2 |

DL |

878±30HLDL 736±40HLDL |

±12 HLDL |

12 HLDL |

|

3 |

C |

822±30HLC 590±40HLC |

±12 HLC |

12 HLC |

Measuring range:HLD(170~960)HLD

Measuring direction:0°~360°

Hardness Scale:HL、HB、HRB、HRC、HRA、HV、HS

Display:segment LCD

Data memory:100 groups max.(relative to impact times 32~1)

Battery: 3.7V Li-Ion, Rechargeable

Battery charger: 5V/500mA

Continuous working period:about 200 hours(With backlight off, no printing)

Communication interface:USB1.1

1.4 Configuration

Table 1-2

|

|

No. |

Item |

Quantity |

Remarks |

|

Standard Config. |

1 |

Main unit |

1 |

D type, C type and DL type optional |

|

2 |

Standard test block |

1 |

|

|

|

3 |

USB cable |

1 |

For comm. And charging |

|

|

4 |

Battery Charger |

1 |

5V 500mA |

|

|

5 |

Cleaning brush I |

1 |

|

|

|

6 |

Small support ring |

1 |

|

|

|

7 |

Li-Ion battery |

1 |

|

|

|

8 |

Manual |

1 |

|

|

|

9 |

DataPro software |

1 |

|

|

|

10 |

Instrument package case |

1 |

|

|

|

Optional Config. |

11 |

Other type of impact devices and support rings |

|

Refer to Table 3 and Table 4 in the appendix. |

|

12 |

|

|

|

Working Conditions

Working temperature: -10℃~+50℃;

Storage temperature:-30℃~+60℃;

Relative humidity: ≤90%;

The surrounding environment should avoid of vibration, strong magnetic field, corrosive medium and heavy dust.

Safety Instructions

The instrument can only work with the specially designed battery pack and power adapter (charger) supplied by Mitech Co. LTD. Working with others may result in damage of the instrument, battery leakage, fire or even explosion.

Do not cast the battery pack into fire and do not short circuit, disassemble or heat the battery pack, otherwise battery leakage, fire or even explosion may occur.

Images of MH100 Hardness Tester