Introduction of MH500 Pen Type Portable Leeb Hardness Gauge

MH500 portable Leeb hardness tester Leeb hardness measurement based on principle, can be quickly and easily on-site detection of a variety of hardness of metal materials, support Leeb, Brielle, Rockwell hardness and other system's free conversion between. It uses a 128 × 64 dot matrix LCD screen, intuitive and information-rich, stable performance, are integrated high-speed thermal printer, enabling printing with instant measurement results, it is widely used in metal processing and manufacturing, special equipment, permanent assembly failure analysis, inspection and other fields. Particularly suitable for large parts and non-removable part of the site hardness testing. It is to improve production efficiency and pass rate, saving the cost of production wise choice.

Feature Purpose of MH500 Pen Type Portable Leeb Hardness Gauge

1)Mold cavity2)Bearings and other parts

3)Failure of the pressure vessel, turbine generator and its equipment Analysis heavy work pieces

4)Mechanical assembly of parts or permanently installed

5)Test space is small work pieces

6)Formal requirements of the test results of original records

7)Material distinguish metal warehouse

8)Rapid testing within a wide range of multiple large parts of the measurement site

Instrument Features of MH500 Pen Type Portable Leeb Hardness Gauge

1)Based Leeb

hardness measuring principle, can detect a variety of metal materials;

2)A host can be equipped with six different impact devices;

3)Support "forged steel (Steel)" material, when using D / DC-type

impact test "Forged" sample, it can directly read the HB value,

without manual look-up table;

4)Hardness value can be pre-set upper and lower limits, out of range alarm,

facilitate the needs of the user volume testing;

5)All Chinese display, menu operation, simple operation, easy;

6)High brightness EL backlight display for easy use in dimly lit environments;

7)It can store up to 500 groups (impact times 32 ~ 1) hardness measurements,

each set of data including single measured value, mean value, measuring date,

impact direction, frequency, material, hardness, and other information;

8)Integrated thermal printer with the instrument as a whole, and quiet

operation, fast print speeds, you can print the test report site;

9)Having a software calibration feature;

10)Built-in NiMH rechargeable batteries and charge control circuit can work for

not less than 150 hours; with automatic sleep, automatic shutdown and other

power-saving features;

11)Real-time display remaining battery charge, charging shows charging

progress;

12)With a USB interface via the optional PC-side data processing software,

transmission measurements, the measured value storage management, statistical

analysis of the measured value, the measured value of the print report, batch

set the instrument parameters to meet the higher requirements of quality assurance

and management;

13)Instrument compact, portable high reliability for harsh operating

environment, anti-vibration, 14)shock and electromagnetic interference;

15)Dimensions: 212mm *80mm * 32mm.

Main Parameter of MH500 Pen Type Portable Leeb Hardness Gauge

|

measuring range |

(170~960)HLD |

|

Measurement direction |

Support for vertical downward, oblique, horizontal, oblique, vertical upward |

|

Indication error |

D type ±6 HLD |

|

Indication repeatability |

D type 6 HLD |

|

Applicable material |

Steel and cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminum alloy, copper zinc alloys (brass), copper tin alloy (bronze) copper forging steel |

|

Unit system |

Richter scale(HL),brudzinski(HB),rockwellB(HRB),rockwellC(HRC),rockwellA(HRA),Victorinox (HV),Shaw(HS) |

|

bombardment energy |

D type 11mJ |

|

Quality of impact body |

D type 5.5g/7.2g |

|

Ball hardness |

D type 1600HV |

|

Diameter of ball head |

D type 3mm |

|

Ball head material |

D type tungsten carbide |

|

Surface roughness of specimen |

D type 1.6μm;C type 0.4μm |

|

Minimum depth of hardened layer |

D type ≥0.8mm;C type ≥0.2mm |

|

display |

Big screen 128*64 Graphic dot matrix liquid crystal display |

|

memory |

Hardness measurement data of maximum 500 sets (32 to 1) of impact times |

|

Calibration function |

Single point calibration |

|

data printing |

Field printing, thermal printer and instrument set to become one |

|

working voltage |

6V Nickel metal hydride battery pack |

|

power supply |

9V/500mA;Charging time 2.5~3.5 hours |

|

Battery Saving Mode |

Low power design |

|

continuous working period |

About 150 hours (no print, no backlight) |

|

communication interface |

USB1.1 |

|

Working language |

Chinese |

|

Shell material |

ABS engineering plastic |

|

Outline dimension |

212mm*80mm*32mm |

|

Weight |

5.5KG |

|

PC client software |

Yes |

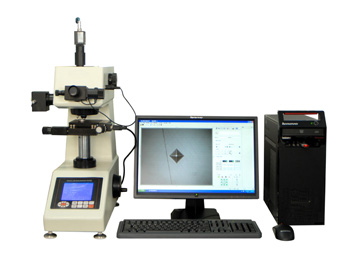

Images of MH500 Pen Type Portable Leeb Hardness Gauge