Introduction Of Cement Spray Machines

Cement Spray Machines is widely used in construction, mining, tunnels, culverts, subway, hydropower engineering, underground engineering and high marsh coal mine tunnel guniting construction operations,various industrial furnaces, repairing or spraying refractory lining and Various green slope, soil transport and injection.The machine can also be used for tidal spray, dry spray and fibers spray.

Featurev Cement Spray Machines

1. Through type rotary, non-sticky, unobstructed discharge, high efficiency and time-saving.

2. Four-point clamping device makes it easy to adjust the press between sealing plate and rotor disk so as to reduce air and dust leak and prolong consumption parts life.,

3. Using low-tension, high-speed vortex pneumatic transportation, so the spraying flow is even, continuous and steady. It's good to improve the guniting quality.

4. The new nozzle, discharge elbow device, improving spray deposition effect, less resilient, high quality guniting layer.

Parameters Of Cement Spray Machines

| Working capacity | 5.5m3/h |

| Max conveying distance | 200m |

| Cement - sand ratio | 1: 3~5 |

| Water-cement ratio | ≤0.4-0.45 |

| Max aggregate dia | Φ20mm |

| Conveying pipe dia | Φ50mm |

| Working pressure | 0.2-0.4Mpa |

| Air consumption | 7-8m3/min |

| Air consumption | 1.1M |

| Rotor speed | 11r/min |

| Power | 5.5kw |

| Voltage class | 380v or 660v |

| Rail distance | 600mm |

| Outer size(L*W*H) | 1520*820*1280mm |

| Machine weight | 650kg |

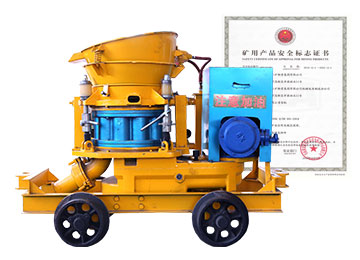

Pictures Of Cement Spray Machines