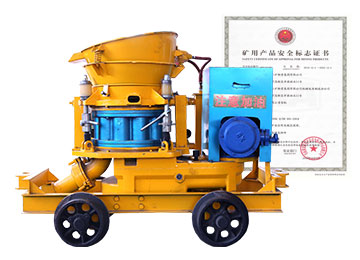

Introduction Of PZ-3 Shotcrete Machine

PZ-3 Dry explosion-proof spraying machine, whether it is wild jet slope, or building wall reinforcement, can meets your needs. And as for the machine, its requirements of the medium is not very high. Any materials can be injected unless the diameter is no more than 20mm..

This kind shotcrete machine uses the compressed air to convey or high-speed jet concrete mix with a certain proportion to the surface through the pipelines. The concrete mix on the surface set and harden to form concrete support layer. In recent years, shotcrete technology with a simple process, an unique effect, the economic cost and fast construction speed, is widely used in construction, rail and road tunnel construction, mine development, slope reinforcement and other fields.

PZ-3-type spraying machine is widely used in construction, mining, tunnels, culverts, subway, hydropower engineering, underground engineering and high marsh coal mine tunnel shotcrete construction operations,various industrial furnaces, repairing or spraying refractory lining and Various green slope, soil transport and injection.1. Through type rotary, non-sticky, unobstructed discharge, high efficiency and time-saving.

2. Four-point clamping device makes it easy to adjust the press between sealing plate and rotor disk so as to reduce air and dust leak and prolong consumption parts life.,

3. Using low-tension, high-speed vortex pneumatic transportation, so the spraying flow is even, continuous and steady. It's good to improve the shotcrete quality.

4. The new nozzle, discharge elbow device, improving spray deposition effect, less resilient, high quality shotcrete.

Maintenance of PZ-3 Shotcrete Machine

(1) After finish work, be sure to clean the machine;

(2) Check all parts of the fastener, particularly the bolts on vibration hopper ;

(3) If have any problem on welded connections, timely treatment;

(4) While material cavity inside the machine, cyclone elbow, sleeve, have a certain release, check the cleaning and timely replace of wearing parts after the end of each class job.

Parameters Of PZ-3 Shotcrete Machine

|

Model |

PZ-3 |

PZ-5 |

PZ-7 |

HSP-5 |

HSP-7 |

HSP-9 |

|

|

Output |

3.5m3/h |

5m3/h |

7m3/h |

4.0-5.0m3/h |

5.0-7.0m3/h |

6.0-9.0m3/h |

|

|

Max. Convey distance |

Horizontal |

200m |

200m |

200m |

30-50m |

30-50m |

30-50m |

|

Vertical |

20m |

20m |

20m |

20m |

20m |

20m |

|

|

Water cement ratio |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

≤0.4 |

|

|

Max. Aggregate. size |

Φ20mm |

Φ20mm |

Φ20mm |

Φ15mm |

Φ15mm |

Φ15mm |

|

|

Hose inner size |

Φ38mm |

Φ51.mm |

Φ64mm |

Φ51mm |

Φ51/64mm |

Φ51/64mm |

|

|

Operating air pressure |

0.4~0.6MPa |

0.4~0.6MPa |

0.4~0.6MPa |

0.3-0.6Mpa |

0.3-0.6Mpa |

0.3-0.6Mpa |

|

|

Air consumption |

3-4 m3/min |

7-8 m3/min |

12-15 m3/min |

10.0-15.0m3/min |

10.0-15.0m3/min |

10.0-15.0m3/min |

|

|

Rotor diameter |

350(150)mm |

438mm |

480mm |

438mm |

480(160)mm |

480(175)mm |

|

|

Voltage |

380v or as your requirement |

380v or as your requirement |

380v or as your requirement |

380v or as your need |

380v or as your need |

380v or as your need |

|

|

Overall dimension mm |

1040*550*940 |

1280*700*1280 |

1600*700*1150 |

1280*700*1280 |

2000*800*1300 |

2000*800*1300 |

|

|

Whole weight |

550kgs |

600kgs |

900kgs |

700kg |

800kg |

900kg |

|

Pictures Of PZ-3 Shotcrete Machine